What is a choke thermostat and why do I need one?

The short answer

A choke thermostat is a component on a carburetor that adjusts the fuel mixture (the percentage of fuel in the fuel/air mixture provided by the carburetor) in order to accommodate the engine's need for a richer mixture when cold. It replaces older, manual choke knobs. Benefits include safety (no driver distraction from fiddling with the choke as the engine warms up), simplicity (achieved by automating the mixture adjustment process, removing the need for the driver to manage it) and fuel economy (no more forgetting to push the choke knob in when the engine is warm).

The longer answer

During normal operation, a gasoline engine requires approximately 14.7:1 ratio of air to fuel (for each gram of fuel, it requires about 14.7 grams of air). Certain conditions (such as hard acceleration) require the carburetor to adjust this mixture in order to avoid knocking, which can damage the engine. The purpose of the carburetor on an engine is to manage this mixture of air and fuel.

When an engine is cold it needs a "richer" mixture in order to run. "Richer" in this sense means that the mixture of fuel and air provided to the engine by the carburetor will have more fuel in it, and less air. (A "leaner" mixture means less fuel and more air). On a carbureted engine, the choke enables a richer mixture to be provided to the engine in order for it to run properly when cold. As the engine warms up, the choke needs to be adjusted to lean out the mixture to achieve the optimum fuel/air ratio (FAR).

In older cars this was achieved manually, through the use of a choke knob. When starting a cold engine the choke knob would be pulled out to richen the mixture, with the driver needing to gradually lean out the mixture as the engine warmed up by incrementally pushing in the choke knob until it was fully pushed in, coinciding with the engine reaching operating temperature. With the advent of the automatic choke, the carburetor was able to take over this mixture adjustment, freeing the driver to concentrate on driving.

Automatic choke designs

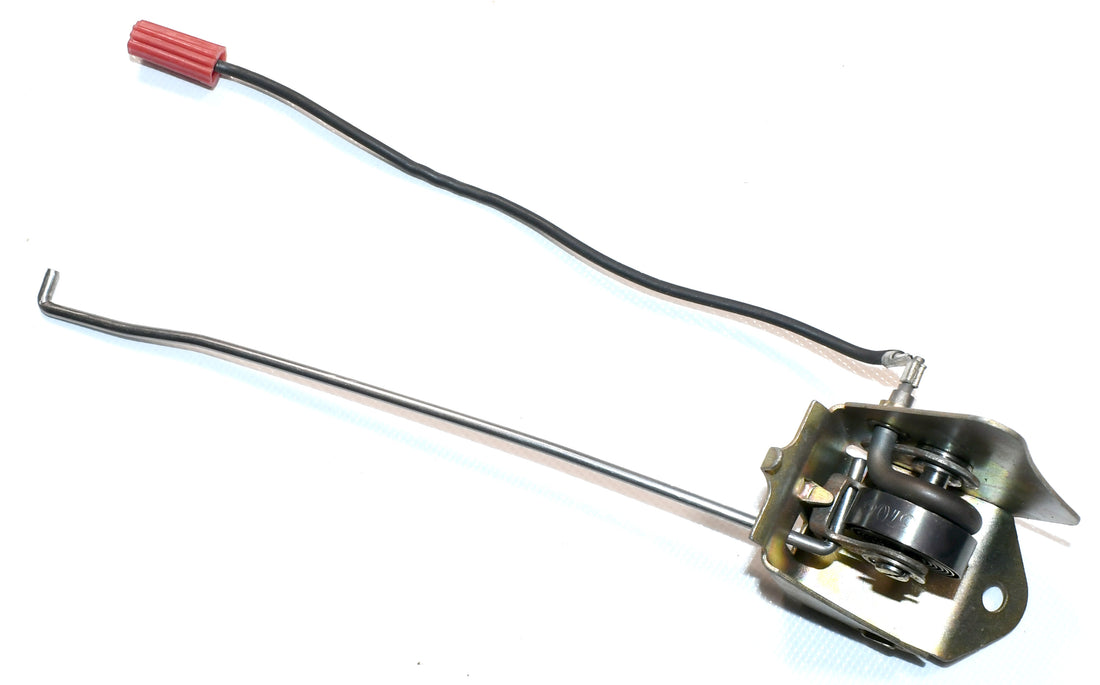

In carbureted cars, there are 2 major designs for automatic choke - electrical or mechanical. Both do essentially the same thing. A bi-metallic coil is used to move a choke flap as the engine warms up. The bi-metallic coil expands when warmed; this actuates the choke linkage that opens the choke flap as the engine warms up. The heating of the bi-metallic spring is done either electrically or using coolant to warm the spring. Using an electric choke, a current passes through the bi-metallic spring, with the electrical resistance in the spring causing it to heat up and expand. With a coolant operated (AKA a mechanical choke), coolant passes through a water jacket around the spring and warms it. In some cases the choke thermostat and water jacket is mounted on the carburetor; in others the choke thermostat is mounted on the intake manifold (called a "divorced choke") with heat coming from the coolant circulating in the intake manifold.

Choke Operation

The illustrations below provide a simplified view of an automatic choke in operation. In the first picture, the engine is cold, so the choke flap closes to choke off the flow of air into the carburetor, creating a richer FAR.

The second illustration shows the engine warmed up, with the choke flap open to allow increase air flow into the carburetor, resulting in a leaner FAR.

Summary

Automatic chokes are a significant improvement over the old, manual choke knob. They are actuated based on temperature, either generated electrically (on an electric choke) or via engine coolant (on a mechanical choke). Either way, they do a great job of managing the mixture requirements inherent in strarting a cold engine. If your engine does not like to start / idle when cold, you may need to replace your choke thermostat. And, as luck would have it, we have them!